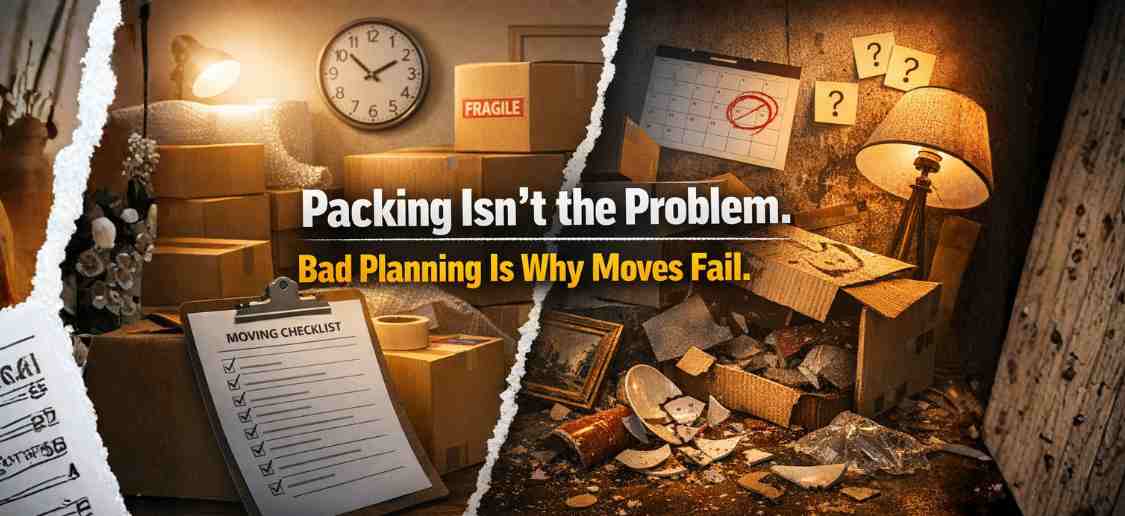

Most people believe moving problems start with packing. Broken items. Missing boxes. Damaged furniture. furniture. That’s what everyone is talking about. But the truth is far more uncomfortable.

Packing is rarely a real problem. Bad planning is.And bad planning doesn’t scream on moving day. It stays quiet—until things start going wrong.

Where Moves Actually Begin to Fail

A relocation doesn’t fail when a box breaks.

It fails much earlier.

It fails when:

- No one knows what goes into which box

- There’s no checklist of items loaded into the truck

- Storage is booked without understanding access or security

- Timelines are assumed, not confirmed

- Responsibility is unclear

At first, everything felt under control. The truck arrives. The packing looks fine.

You relax. That’s when the damage starts.

The Fear Nobody Talks About

The real fear during relocation isn’t loud chaos.

It’s silent. Silence when:

- A box doesn’t arrive

- Inventory numbers don’t match

- The storage facility says “we’ll check”

- You can’t trace where your item went missing

- No one can clearly answer who handled what

That quiet confusion turns into a panic situation. Because once something is lost, you can’t rewind a move.

Packing Without Planning Is Just Guesswork

Even the best packing fails if planning is weak.

Here’s what bad planning looks like:

- Items packed without inventory tagging

- No segregation between fragile, valuable, and regular goods

- Shared storage spaces without clear ownership

- No system to track entry and exit

- No accountability once goods leave your sight

At this point, theft, damage, or loss doesn’t need effort. It happens naturally. Not because someone planned it—but because no one planned it properly.

Why Most Relocations Feel Stressful

People don’t feel stressed because of heavy boxes.

They feel stressed because of uncertainty.

Questions like:

- “Is everything loaded?”

- “Where is that box?”

- “Who handled this?”

- “What if something is missing?”

Fear comes from not knowing and bad planning creates too many unknowns.

How Proper Planning Stops Problems Before They Start

Good relocation planning doesn’t react to issues. It prevents them.

This includes:

- Pre-move inventory listing

- Clear labelling and tracking

- Controlled handling at every stage

- Organised storage, not cluttered space

- Defined processes instead of assumptions

When systems are strong, mistakes have nowhere to hide.

Where Xtended Space Changes the Game

This is where Xtended Space stands apart. Xtended Space doesn’t treat relocation as just packing and transport. It treats it as a planned operation. From structured packing protocols to organized storage systems, the focus stays on visibility and control. Goods aren’t just moving—they’re tracked, managed, and handled with accountability. Storage isn’t a random space. It’s planned storage with defined access, monitoring, and order. That’s how fear is reduced—not by promises, but by systems.

The Cost of Ignoring Planning

When planning is ignored:

- Loss feels “normal”

- Stress becomes expected

- Trust breaks down

- Customers accept damage as unavoidable

But damage is not inevitable.Loss is not normal.

Stress is not part of relocation—it’s a sign of weak planning.

Final Thought

Packing doesn’t ruin moves. Bad planning does.

If your relocation depends on hope instead of structure, you’re taking a risk—whether you realize it or not. Good planning works quietly. Just like the problems it prevents.

FAQs

- Why do most relocations face issues even with good packing?

Packing without proper planning means poor tracking, accountability, and control. - When do relocation problems usually begin?

Much before moving day—during inventory planning, storage decisions, and process gaps. - Is damage always caused during transportation?

No. Most issues start due to poor handling, unclear labelling, or weak storage systems. - How does planning reduce relocation stress?

Planning removes uncertainty by creating visibility and responsibility at every stage. - How doesXtendedSpace help prevent relocation failures?

By focusing on structured processes, organised storage, tracking systems, and controlled handling.